Product Description

Product Description

Product introduction

| Gear processing modules | 0.5-20 |

| Max. machining diamete for gear milling | 1720mm |

| Max. main shaft through-hole diameter for gear grinding | 180mm |

| Max, main shaft through-hole diameter for gear milling | 320mm |

| Max. machining diameter for gear grinding | 850mm |

| Highest precision | GB11365-89 4 grade |

| Transmission ratio | 1:1-1:10 |

My advantages:

1. High quality materials, professional production, high-precision equipment. Customized design and processing;

2. Strong and durable, strong strength, large torque and good comprehensive mechanical properties;

3. High rotation efficiency, stable and smooth transmission, long service life, noise reduction and shock absorption;

4. Focus on gear processing for 20 years.

5. Carburizing and quenching of tooth surface, strong wear resistance, reliable operation and high bearing capacity;

6. The tooth surface can be ground, and the precision is higher after grinding.

The company is a manufacturer of high-quality leather wheel transmission components and mechanical transmission equipment. Its products are widely used in various fields such as aviation, aerospace, shipbuilding, rail transit, engineering vehicles, and industrial automation equipment. The company was founded in December 2002, and its factory is located in Xihu (West Lake) Dis.ng Industrial Zone, Jiangfu City, ZheJiang Province. The existing factory building covers an area of 38000 square meters, with a registered capital of 20 million yuan and a total asset of about 180 million yuan. It has passed the CCs ship inspection and recognition by China’s classification society, and has been rated as a high-tech enterprise in ZheJiang Province and the ZheJiang High Precision Gear Transmission Key Component Engineering Technology Research Center.

The company has the most advanced manufacturing and testing equipment for bright precision gear transmission components in the world, with manufacturing accuracy CZPT national standard 3-4 levels. It has 275G and 800G CNC Yawei gear grinding machines from Grissom Phoenix, Germany, Capa vX55 and VX59 CNC gear grinding centers from Germany, ZE400 and ZE8OO shaped gear grinding machines from Capa Niles, worm gear grinding machines from Germany, Graub 5-extraction linkage machining center from Germany, KS42 high-precision straight bevel gear grinding machine from Switzerland, Teng gear grinding machine from Switzerland, S33 high-precision CNC universal domestic and foreign grinding machine from Stuttgart, Switzerland, and GMM1500 gear measuring center from Grissom GMM1500, Zeiss Santang, Germany.

After years of testing, exploration, and improvement, the company’s research and development team has mastered key technologies such as high-precision gear CNC grinding technology, inspection technology, heat treatment technology for thin-walled parts, independent design and manufacturing technology for special cutters, fixtures, and special measuring tools. At present, the company’s manufacturing capacity and technical development level rank among the leading levels of domestic peers.

FAQ

| Main Markets? | North America, South America, Eastern Europe , West Europe , North Europe, South Europe, Asia |

| How to order? | * You send us drawing or sample |

| * We carry through project assessment | |

| * We give you our design for your confirmation | |

| * We make the sample and send it to you after you confirmed our design | |

| * You confirm the sample then place an order and pay us 30% deposit | |

| * We start producing | |

| * When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers. | |

| * Trade is done, thank you!! |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 60/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

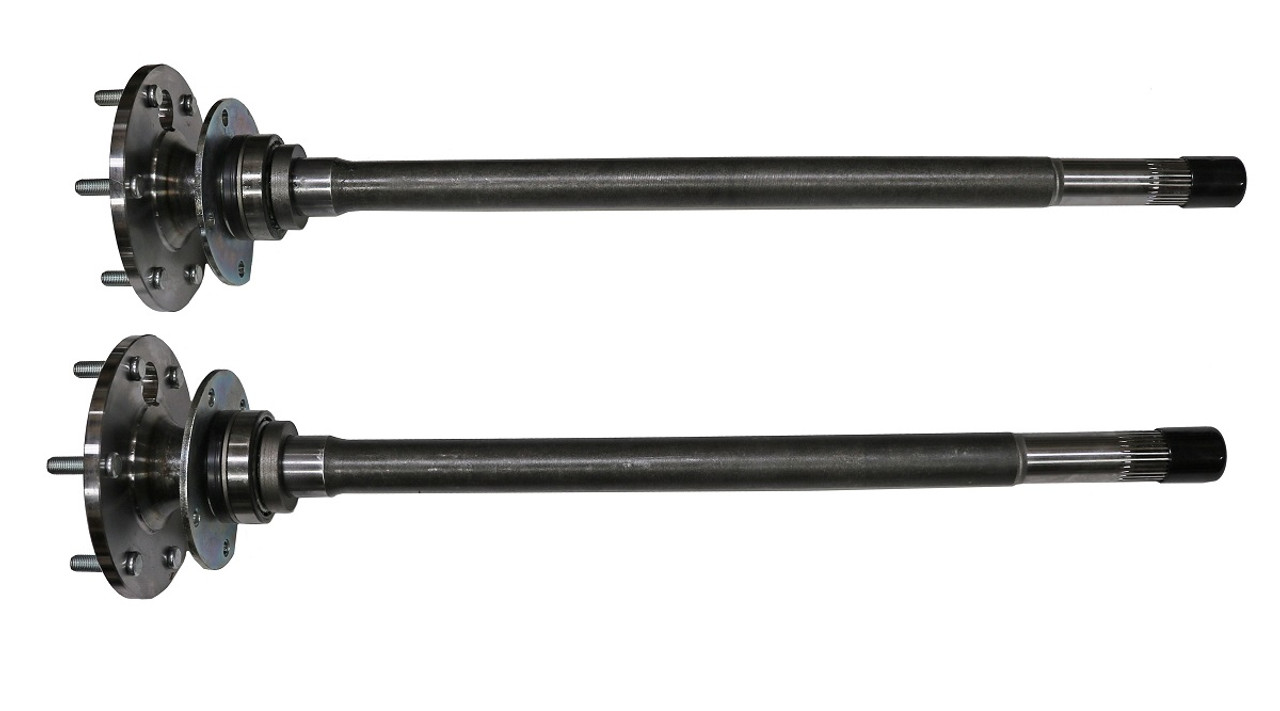

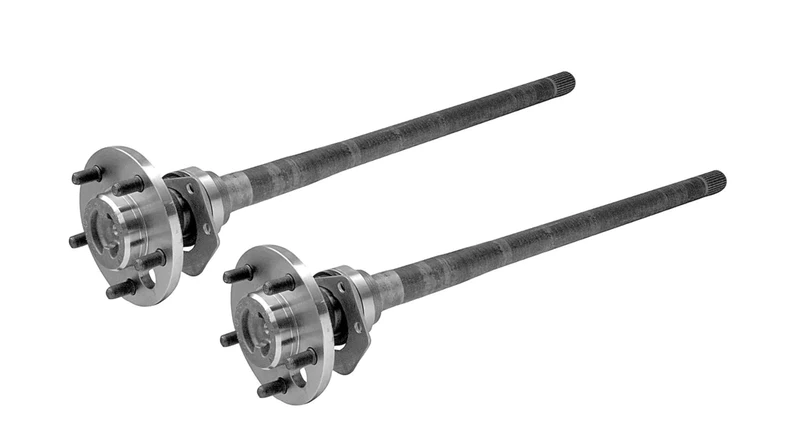

Can you explain the impact of axle shaft materials on weight and strength?

The choice of material for axle shafts has a significant impact on both weight and strength characteristics. Different materials offer varying levels of strength-to-weight ratios, which can influence the overall performance and durability of the axle shafts. Here’s an explanation of how axle shaft materials affect weight and strength:

- Steel: Steel is a commonly used material for axle shafts due to its high strength and durability. Steel axle shafts are known for their excellent load-bearing capacity and resistance to bending and torsional forces. However, steel is relatively heavy compared to other materials, which can contribute to increased overall weight of the vehicle. The weight of steel axle shafts can affect the vehicle’s fuel efficiency and handling characteristics.

- Alloy Steel: Alloy steel is a type of steel that has been mixed with other elements to enhance specific properties. By adding elements such as chromium, molybdenum, or nickel, alloy steel can achieve improved strength and hardness compared to traditional steel. This allows for the production of lighter and stronger axle shafts compared to conventional steel, providing a balance between weight reduction and structural integrity.

- Aluminum: Aluminum is a lightweight material known for its excellent strength-to-weight ratio. When used in axle shafts, aluminum can significantly reduce the weight of the component, which can lead to benefits such as improved fuel efficiency and handling. However, aluminum axle shafts may not be as strong as steel shafts and can be more susceptible to bending or deformation under high loads or extreme conditions.

- Composite Materials: Composite materials, such as carbon fiber reinforced polymers (CFRP), are increasingly being explored for axle shaft applications. CFRP composites offer high strength and light weight, making them attractive for weight reduction purposes. These materials can provide comparable or even superior strength compared to steel while significantly reducing the overall weight of the axle shafts. However, composite materials often come with higher production costs and may require specialized manufacturing techniques.

Overall, the choice of axle shaft material involves a trade-off between weight reduction and strength requirements. Steel offers excellent strength but comes with higher weight, while materials like aluminum and composites offer weight savings at the expense of some strength characteristics. The selection of the most suitable material depends on various factors, including the vehicle’s intended use, load requirements, cost considerations, and desired performance attributes.

In summary, the impact of axle shaft materials on weight and strength is significant. Steel provides high strength but adds weight, alloy steel offers a balance between strength and weight, aluminum reduces weight but may sacrifice some strength, and composite materials provide strength and weight advantages but at potentially higher costs. Manufacturers consider these factors when selecting axle shaft materials to achieve the desired balance of weight reduction, strength, and overall performance in vehicles.

How does axle shaft quality impact the overall durability of a vehicle?

The quality of axle shafts has a significant impact on the overall durability of a vehicle. Axle shafts play a crucial role in transmitting power from the drivetrain to the wheels and supporting the weight of the vehicle. Here’s a detailed explanation of how axle shaft quality affects the durability of a vehicle:

- Strength and Load Capacity: High-quality axle shafts are typically constructed from strong and durable materials, such as forged steel or alloy steel. These materials offer increased tensile and yield strength, allowing the axle shafts to handle higher torque loads and support the weight of the vehicle more effectively. Axle shafts with higher load capacities and structural integrity are less prone to bending, breaking, or premature failure, ensuring long-term durability.

- Resistance to Fatigue: Axle shafts are subjected to repeated and varying loads during vehicle operation, which can lead to metal fatigue over time. High-quality axle shafts are designed and manufactured to withstand these cyclic loads without developing cracks or fractures. They undergo rigorous testing and quality control processes to ensure resistance to fatigue, enhancing the overall durability of the vehicle.

- Corrosion Resistance: Axle shafts are exposed to various environmental factors, including moisture, road salt, and debris. High-quality axle shafts often feature protective coatings or treatments, such as galvanization or specialized finishes, to enhance corrosion resistance. These coatings prevent rust and corrosion from compromising the structural integrity of the axle shafts, contributing to their long-term durability.

- Precision Engineering: Axle shafts with superior quality are precisely engineered to meet strict tolerances and specifications. They are manufactured using advanced techniques, such as forging or CNC machining, to ensure dimensional accuracy and proper fitment with other drivetrain components. Precise engineering eliminates excessive play or misalignment, reducing stress on the axle shafts and enhancing the overall durability of the vehicle.

- Heat Treatment: High-quality axle shafts often undergo specialized heat treatment processes, such as induction hardening or tempering. These heat treatment techniques improve the hardness and strength of the axle shafts, making them more resistant to wear, deformation, and surface damage. Heat-treated axle shafts exhibit enhanced durability and longevity, even under demanding driving conditions.

- Manufacturer Reputation: The reputation of the axle shaft manufacturer is also a crucial factor in determining the quality and durability of the product. Reputable manufacturers with a history of producing reliable and high-quality axle shafts are more likely to deliver durable and long-lasting components. Choosing axle shafts from trusted manufacturers reduces the risk of premature failure and ensures higher overall vehicle durability.

It’s important to note that the durability of a vehicle is influenced by various other factors, including proper maintenance, driving conditions, and overall vehicle design. However, the quality of axle shafts significantly contributes to the vehicle’s ability to withstand demanding loads, harsh environments, and extended service life.

When replacing or upgrading axle shafts, it is crucial to select high-quality components that match the vehicle’s specifications and intended use. Professional installation by experienced technicians is recommended to ensure proper fitment and compatibility, further enhancing the durability and performance of the vehicle.

In summary, axle shaft quality directly impacts the overall durability of a vehicle by providing increased strength, resistance to fatigue and corrosion, precision engineering, heat treatment, and the reliability associated with reputable manufacturers. Investing in high-quality axle shafts contributes to a more durable and reliable vehicle that can withstand the demands of various driving conditions and extended use.

Can you explain the different types of axle shafts used in automobiles?

Automobiles utilize different types of axle shafts depending on the vehicle’s drivetrain configuration, suspension design, and intended use. Here are some of the commonly used axle shaft types:

1. Solid Axle Shaft:

A solid axle shaft, also known as a full-floating axle, is a single, rigid shaft that connects the differential to the wheels. It is commonly used in rear-wheel-drive vehicles, trucks, and off-road vehicles. Solid axle shafts provide robustness and strength, making them suitable for heavy-duty applications. They are capable of handling high torque loads and are relatively simple in design. However, solid axle shafts can contribute to a harsher ride and increased unsprung weight compared to other axle types.

2. Split Axle Shaft:

A split axle shaft, also referred to as a semi-floating axle, consists of two separate shafts that connect the differential to each wheel independently. Split axle shafts are commonly used in light-duty passenger vehicles and some rear-wheel-drive trucks. Each shaft supports the weight of its corresponding wheel and transmits torque. Split axle shafts offer a balance between strength and weight savings compared to solid axle shafts. However, they are generally not as robust as full-floating axles and may have lower load-carrying capacity.

3. Half Shaft:

A half shaft, also known as a drive shaft or CV axle, is commonly used in front-wheel-drive and all-wheel-drive vehicles. It connects the differential or transaxle to the front wheels, allowing power transmission and wheel rotation. Half shafts are typically equipped with constant velocity (CV) joints, which accommodate the articulation and angle changes during suspension movement and steering. CV joints enable smooth power transfer and minimize vibrations. Half shafts are usually lighter and more compact than solid or split axle shafts and are designed to handle the demands of front-wheel-drive systems.

4. Torque Tube Axle:

A torque tube axle is an older design that was used in some early automobiles. It consists of a single tube that encases the driveshaft and connects the differential to the wheels. The torque tube axle provides power transmission and support for the wheels but lacks independent suspension. This design has largely been phased out in modern vehicles, as it limits suspension flexibility and can contribute to a harsher ride quality.

5. Independent Rear Suspension Axle Shafts:

In vehicles with independent rear suspension (IRS), each wheel typically has its own axle shaft. These axle shafts connect the differential to the individual wheels and allow independent movement and suspension articulation. Independent rear suspension axle shafts are commonly found in modern passenger cars and some high-performance vehicles. They provide improved handling, ride comfort, and traction compared to solid axle shafts. The design and construction of these axle shafts may vary depending on the specific IRS system implemented in the vehicle.

It’s important to note that the specific axle shaft types used in automobiles can vary depending on the vehicle manufacturer, model, and drivetrain configuration. Additionally, advancements in technology and the increasing popularity of electric vehicles may introduce new axle shaft designs and materials in the future.

In summary, the different types of axle shafts used in automobiles include solid axle shafts, split axle shafts, half shafts, torque tube axles (less common in modern vehicles), and independent rear suspension axle shafts. Each type has its own advantages and is tailored to specific vehicle applications and requirements.

editor by CX 2024-05-10

China Professional Carbon Steel High Precision CNC Machining Shaft OEM Gear Shaft Turning Axle Stainless Steel Motor Shaft axle fix cost

Product Description

carbon steel high precision CNC machining shaft OEM gear shaft turning axle stainless steel motor shaft

| Product name | CNC machining services |

| Surface treatment | Zinc- Plated , Nickel-plated,Tin-plated , Passivated , Sandblast and Anodize, Chromate, Polish , Black Oxide , Dacromet,Hot Deep Galvanize(H. D. G. ) etc. |

| Grade | Steel,A2-70, A2-80, A4-80, SUS304, SUS316 ,GR2,GR5,BRASS,Aluminium |

| Standard | ISO,BS,ANSI, GB,DIN,JIS,Nonstandard |

| Advantage | OEM / ODM / customized service provided;We are factory, we could make the size as your requirment. |

| Quality control | ISO standard,100% Whole range inspection through the production |

| Certificate | ISO9001:2008, SGS, ROHS |

| Payment term | TT 30% deposit in advance, 70% Balance Before ship |

How to order?

Please provide the product you need parameters:

1. You need the product name

2. You need the amount of products

3. You need the material of products

4. You need the product specifications

Because it is convenient we can more quickly to give you a quotation. Thanks!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Fastener, Auto and Motorcycle Accessory, Hardware Tool, Machinery Accessory |

|---|---|

| Standard: | GB, EN, JIS Code, ASME |

| Production Type: | Single Production |

| Machining Method: | CNC Turning |

| Material: | Nylon, Steel, Plastic, Brass, Alloy, Copper, Aluminum, Iron |

| Transport Package: | Original Packing/According to Your Requirement |

| Samples: |

US$ 150/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can axle shafts be used in various types of vehicles, from compact cars to heavy trucks?

Axle shafts are integral components of the drivetrain system in vehicles, and they are indeed used in a wide range of vehicle types, spanning from compact cars to heavy trucks. Axle shafts play a critical role in transmitting torque from the differential to the wheels, allowing for power delivery and enabling vehicle movement. Here’s a detailed explanation of how axle shafts are utilized in different types of vehicles:

Compact Cars and Sedans: Compact cars and sedans typically employ a front-wheel drive or rear-wheel drive configuration. In these vehicles, the axle shafts are responsible for transmitting power from the differential to the drive wheels. In front-wheel drive vehicles, the axle shafts connect the transaxle (combining the transmission and differential) to the front wheels. In rear-wheel drive vehicles, the axle shafts transmit power from the rear differential to the rear wheels. Axle shafts in compact cars and sedans are generally designed to handle the power and load requirements specific to these vehicle classes.

SUVs and Crossovers: Sport utility vehicles (SUVs) and crossovers often feature both front-wheel drive and all-wheel drive configurations. In these vehicles, axle shafts are utilized to transfer power to the drive wheels, whether it’s the front wheels, rear wheels, or all wheels simultaneously. In all-wheel drive systems, axle shafts connect the front and rear differentials to the respective wheels, enabling power distribution to all four wheels. The axle shafts in SUVs and crossovers are designed to handle the higher power and torque demands associated with these larger and more capable vehicles.

Pickup Trucks and Vans: Pickup trucks and vans are commonly rear-wheel drive or four-wheel drive vehicles. Rear-wheel drive trucks employ axle shafts to transmit power from the rear differential to the rear wheels, enabling propulsion. Four-wheel drive trucks and vans utilize both front and rear axle shafts to distribute power to all four wheels. These vehicles often require robust and heavy-duty axle shafts capable of handling the increased loads, towing capacities, and off-road conditions associated with these applications.

Heavy Trucks and Commercial Vehicles: Heavy trucks and commercial vehicles, such as tractor-trailers, buses, and construction vehicles, have specialized axle systems to support their substantial weight and demanding operating conditions. These vehicles typically employ multiple axles, including front steer axles and drive axles. Axle shafts in heavy trucks are designed to withstand high torque, heavy loads, and challenging terrains. They are constructed using durable materials and feature robust designs to ensure reliable performance and longevity.

Overall, axle shafts are utilized in various types of vehicles, ranging from compact cars to heavy trucks. They play a crucial role in transmitting power from the differential to the wheels, enabling vehicle movement. The design, materials, and specifications of axle shafts vary depending on the vehicle class, power requirements, and intended application.

In summary, axle shafts are essential components in a wide range of vehicles, from compact cars and sedans to SUVs, pickup trucks, heavy trucks, and commercial vehicles. Their function is to transfer power from the differential to the drive wheels, facilitating vehicle propulsion. The design and characteristics of axle shafts are tailored to meet the specific needs of each vehicle type, ensuring optimal performance and durability.

How do axle shafts contribute to a vehicle’s stability and handling?

Axle shafts play a crucial role in contributing to a vehicle’s stability and handling characteristics. They are integral components of the suspension and drivetrain systems, affecting how the vehicle distributes power, maintains traction, and responds to steering inputs. Here’s a detailed explanation of how axle shafts contribute to a vehicle’s stability and handling:

- Power Distribution: Axle shafts transmit power from the drivetrain to the wheels, allowing the vehicle to move forward or backward. The distribution of power between the wheels is essential for maintaining stability and preventing wheel slippage. By transferring torque evenly to the wheels, axle shafts help optimize traction and prevent excessive power loss, ensuring that the vehicle stays stable and controlled during acceleration or deceleration.

- Traction Control: Axle shafts, particularly those equipped with differential mechanisms, help maintain traction by allowing the wheels to rotate at different speeds when necessary. This feature is especially important during turns or when driving on uneven surfaces. The differential compensates for differences in wheel rotation, enabling the vehicle to maintain stability and grip by preventing wheel spin or loss of control.

- Suspension Geometry: Axle shafts are integrated into the suspension system, connecting the wheels to the differential or transaxle. The positioning and design of axle shafts influence the suspension geometry, including factors like camber, caster, and toe. Proper suspension geometry is crucial for stability, predictable handling, and optimal tire contact with the road surface. Well-engineered axle shafts ensure that the suspension components work harmoniously to maintain stability and enhance handling characteristics.

- Steering Response: In vehicles with front-wheel drive or all-wheel drive configurations, axle shafts are responsible for transmitting power to the front wheels while also allowing for steering inputs. This design affects the vehicle’s steering response and handling. High-quality axle shafts with minimal play or backlash contribute to precise steering control, allowing the driver to make accurate and predictable maneuvers. Axle shafts that provide a direct and responsive connection between the drivetrain and front wheels enhance the overall handling and stability of the vehicle.

- Weight Distribution: The weight distribution of a vehicle affects its stability and handling characteristics. Axle shafts, particularly those in rear-wheel drive vehicles, support the weight of the vehicle’s rear end. By properly distributing the weight across the axles, axle shafts help maintain a balanced and stable platform. This balanced weight distribution enhances the vehicle’s overall stability and allows for better handling during cornering, reducing the risk of oversteer or understeer.

- Impact on Suspension Tuning: Axle shafts can have an impact on the tuning and performance of the suspension system. Upgrading to high-performance axle shafts, such as those made from stronger materials or featuring improved designs, can enhance the overall rigidity and responsiveness of the suspension. This, in turn, improves the vehicle’s stability and handling, allowing for more precise control during aggressive driving or challenging road conditions.

It’s important to note that while axle shafts contribute significantly to a vehicle’s stability and handling, they work in conjunction with other components such as suspension, tires, steering system, and chassis design. The overall performance and characteristics of a vehicle’s stability and handling are the result of a complex interaction between these components.

In summary, axle shafts contribute to a vehicle’s stability and handling by ensuring proper power distribution, maintaining traction control, influencing suspension geometry, providing responsive steering, contributing to balanced weight distribution, and impacting suspension tuning. High-quality axle shafts that are properly engineered and integrated into the vehicle’s systems enhance stability, improve handling characteristics, and allow for a more controlled and enjoyable driving experience.

What is the purpose of an axle shaft in a vehicle’s drivetrain?

An axle shaft plays a crucial role in a vehicle’s drivetrain by transmitting rotational power from the differential to the wheels. It serves as a mechanical link between the differential and the wheels, allowing the transfer of torque and enabling the wheels to rotate.

1. Power Transmission:

The primary purpose of an axle shaft is to transmit power from the differential to the wheels. In a rear-wheel-drive vehicle, the axle shafts connect the differential to the rear wheels, while in a front-wheel-drive vehicle, they connect the differential or transaxle to the front wheels. When the engine generates torque, it is transferred to the transmission or transaxle, and then to the differential. The differential splits the torque between the two axle shafts, which then deliver the power to the respective wheels. This allows the wheels to rotate and propel the vehicle forward or backward.

2. Wheel Support and Suspension:

Axle shafts also provide support for the vehicle’s wheels and are an integral part of the suspension system. They bear the weight of the vehicle and help maintain proper wheel alignment and geometry. Axle shafts are designed to withstand the vertical load exerted by the vehicle’s weight and the lateral forces encountered during turns or maneuvering. By providing structural support and connection between the wheels and the drivetrain, axle shafts contribute to the overall stability, handling, and control of the vehicle.

3. Differential Functionality:

Axle shafts are essential for the proper functioning of the differential. The differential allows the wheels to rotate at different speeds while maintaining power distribution. As the vehicle negotiates turns, the inside wheels travel a shorter distance than the outside wheels. The axle shafts, connected to the differential, enable this speed differentiation by allowing the wheels to rotate independently. This differential action helps improve maneuverability, reduce tire wear, and enhance traction by allowing the wheels to maintain proper contact with the road surface.

4. Torque and Load Handling:

Axle shafts are designed to handle the torque and loads generated by the engine and transmitted through the drivetrain. They are engineered to withstand the rotational forces and torsional stress, ensuring efficient power transfer to the wheels. Axle shafts are made from durable materials, such as steel or other high-strength alloys, to withstand these forces and provide reliable performance under various driving conditions.

In summary, the purpose of an axle shaft in a vehicle’s drivetrain is to transmit rotational power from the differential to the wheels. They enable power transfer, provide support for the wheels, contribute to the functionality of the differential, and handle the torque and loads generated by the drivetrain. Axle shafts are essential components that play a vital role in the overall performance, functionality, and stability of a vehicle.

editor by CX 2024-05-09

China Professional Rotary Power Grinding Axle Z10 Transmission Spur Gear Shaft axle deadlift

Product Description

Rotary Power Grinding Axle Z10 Transmission Spur Gear Shaft

Gear transmission relies on the thrust between gear teeth to transmit motion and power, also known as meshing transmission. With this gradual meshing, helical gears operate much more smoothly and quietly than spur gears. Therefore, almost all automobile transmissions use helical gears.Since the teeth on the helical gear present a certain angle, the gears will be under a certain amount of stress when they mesh. Equipment using helical gears is equipped with bearings to withstand this pressure.

Product Parameters

| Product name | Spur Gear & Helical Gear & Gear Shaft |

| Customized service | OEM, drawings or samples customize |

| Materials Available | Stainless Steel, Carbon Steel, S45C, SCM415, 20CrMoTi, 40Cr, Brass, SUS303/304, Bronze, Iron, Aluminum Alloy etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Surface Treatment | Conditioning, Carburizing and Quenching,Tempering ,High frequency quenching, Tempering, Blackening, QPQ, Cr-plating, Zn-plating, Ni-plating, Electroplate, Passivation, Picking, Plolishing, Lon-plating, Chemical vapor deposition(CVD), Physical vapour deposition(PVD)… |

| BORE | Finished bore, Pilot Bore, Special request |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Pressure Angle | 20 Degree |

| Hardness | 55- 60HRC |

| Size | Customer Drawings & ISO standard |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001:2008 |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Printing Equipment Industry, Laser Equipment Industry, Automated Assemblyline Industry, Woodening Industry, Packaging Equipment Industry, Logistics storage Machinery Industry, Robot Industry, Machine Tool Equipment Industry |

| Advantages | 1. Produce strictly in accordance with ANSI or DIN standard dimension 2. Material: SCM 415 steel 3. Bore: Finished bore 4. Precision grade: DIN 5 to DIN 7 5. Surface treatment: Carburizing and Quenching 6. Module: From 1 to 4 7. Tooth: From Z15 to Z70 |

Company Profile

Packaging & Shipping

FAQ

| Main markets | North America, South America,Eastern Europe,Weat Europe,North Europe.South Europe,Asia |

| How to order | *You send us drawing or sample |

| *We carry through project assessment | |

| *We give you our design for your confirmation | |

| *We make the sample and send it to you after you confirmed our design | |

| *You confirm the sample then place an order and pay us 30% deposit | |

| *We start producing | |

| *When the goods is done,you pay us the balance after you confirmed pictures or tracking numbers | |

| *Trade is done,thank you! |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car, Laser Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you explain the impact of axle shaft materials on weight and strength?

The choice of material for axle shafts has a significant impact on both weight and strength characteristics. Different materials offer varying levels of strength-to-weight ratios, which can influence the overall performance and durability of the axle shafts. Here’s an explanation of how axle shaft materials affect weight and strength:

- Steel: Steel is a commonly used material for axle shafts due to its high strength and durability. Steel axle shafts are known for their excellent load-bearing capacity and resistance to bending and torsional forces. However, steel is relatively heavy compared to other materials, which can contribute to increased overall weight of the vehicle. The weight of steel axle shafts can affect the vehicle’s fuel efficiency and handling characteristics.

- Alloy Steel: Alloy steel is a type of steel that has been mixed with other elements to enhance specific properties. By adding elements such as chromium, molybdenum, or nickel, alloy steel can achieve improved strength and hardness compared to traditional steel. This allows for the production of lighter and stronger axle shafts compared to conventional steel, providing a balance between weight reduction and structural integrity.

- Aluminum: Aluminum is a lightweight material known for its excellent strength-to-weight ratio. When used in axle shafts, aluminum can significantly reduce the weight of the component, which can lead to benefits such as improved fuel efficiency and handling. However, aluminum axle shafts may not be as strong as steel shafts and can be more susceptible to bending or deformation under high loads or extreme conditions.

- Composite Materials: Composite materials, such as carbon fiber reinforced polymers (CFRP), are increasingly being explored for axle shaft applications. CFRP composites offer high strength and light weight, making them attractive for weight reduction purposes. These materials can provide comparable or even superior strength compared to steel while significantly reducing the overall weight of the axle shafts. However, composite materials often come with higher production costs and may require specialized manufacturing techniques.

Overall, the choice of axle shaft material involves a trade-off between weight reduction and strength requirements. Steel offers excellent strength but comes with higher weight, while materials like aluminum and composites offer weight savings at the expense of some strength characteristics. The selection of the most suitable material depends on various factors, including the vehicle’s intended use, load requirements, cost considerations, and desired performance attributes.

In summary, the impact of axle shaft materials on weight and strength is significant. Steel provides high strength but adds weight, alloy steel offers a balance between strength and weight, aluminum reduces weight but may sacrifice some strength, and composite materials provide strength and weight advantages but at potentially higher costs. Manufacturers consider these factors when selecting axle shaft materials to achieve the desired balance of weight reduction, strength, and overall performance in vehicles.

How do axle shafts contribute to a vehicle’s stability and handling?

Axle shafts play a crucial role in contributing to a vehicle’s stability and handling characteristics. They are integral components of the suspension and drivetrain systems, affecting how the vehicle distributes power, maintains traction, and responds to steering inputs. Here’s a detailed explanation of how axle shafts contribute to a vehicle’s stability and handling:

- Power Distribution: Axle shafts transmit power from the drivetrain to the wheels, allowing the vehicle to move forward or backward. The distribution of power between the wheels is essential for maintaining stability and preventing wheel slippage. By transferring torque evenly to the wheels, axle shafts help optimize traction and prevent excessive power loss, ensuring that the vehicle stays stable and controlled during acceleration or deceleration.

- Traction Control: Axle shafts, particularly those equipped with differential mechanisms, help maintain traction by allowing the wheels to rotate at different speeds when necessary. This feature is especially important during turns or when driving on uneven surfaces. The differential compensates for differences in wheel rotation, enabling the vehicle to maintain stability and grip by preventing wheel spin or loss of control.

- Suspension Geometry: Axle shafts are integrated into the suspension system, connecting the wheels to the differential or transaxle. The positioning and design of axle shafts influence the suspension geometry, including factors like camber, caster, and toe. Proper suspension geometry is crucial for stability, predictable handling, and optimal tire contact with the road surface. Well-engineered axle shafts ensure that the suspension components work harmoniously to maintain stability and enhance handling characteristics.

- Steering Response: In vehicles with front-wheel drive or all-wheel drive configurations, axle shafts are responsible for transmitting power to the front wheels while also allowing for steering inputs. This design affects the vehicle’s steering response and handling. High-quality axle shafts with minimal play or backlash contribute to precise steering control, allowing the driver to make accurate and predictable maneuvers. Axle shafts that provide a direct and responsive connection between the drivetrain and front wheels enhance the overall handling and stability of the vehicle.

- Weight Distribution: The weight distribution of a vehicle affects its stability and handling characteristics. Axle shafts, particularly those in rear-wheel drive vehicles, support the weight of the vehicle’s rear end. By properly distributing the weight across the axles, axle shafts help maintain a balanced and stable platform. This balanced weight distribution enhances the vehicle’s overall stability and allows for better handling during cornering, reducing the risk of oversteer or understeer.

- Impact on Suspension Tuning: Axle shafts can have an impact on the tuning and performance of the suspension system. Upgrading to high-performance axle shafts, such as those made from stronger materials or featuring improved designs, can enhance the overall rigidity and responsiveness of the suspension. This, in turn, improves the vehicle’s stability and handling, allowing for more precise control during aggressive driving or challenging road conditions.

It’s important to note that while axle shafts contribute significantly to a vehicle’s stability and handling, they work in conjunction with other components such as suspension, tires, steering system, and chassis design. The overall performance and characteristics of a vehicle’s stability and handling are the result of a complex interaction between these components.

In summary, axle shafts contribute to a vehicle’s stability and handling by ensuring proper power distribution, maintaining traction control, influencing suspension geometry, providing responsive steering, contributing to balanced weight distribution, and impacting suspension tuning. High-quality axle shafts that are properly engineered and integrated into the vehicle’s systems enhance stability, improve handling characteristics, and allow for a more controlled and enjoyable driving experience.

What is the purpose of an axle shaft in a vehicle’s drivetrain?

An axle shaft plays a crucial role in a vehicle’s drivetrain by transmitting rotational power from the differential to the wheels. It serves as a mechanical link between the differential and the wheels, allowing the transfer of torque and enabling the wheels to rotate.

1. Power Transmission:

The primary purpose of an axle shaft is to transmit power from the differential to the wheels. In a rear-wheel-drive vehicle, the axle shafts connect the differential to the rear wheels, while in a front-wheel-drive vehicle, they connect the differential or transaxle to the front wheels. When the engine generates torque, it is transferred to the transmission or transaxle, and then to the differential. The differential splits the torque between the two axle shafts, which then deliver the power to the respective wheels. This allows the wheels to rotate and propel the vehicle forward or backward.

2. Wheel Support and Suspension:

Axle shafts also provide support for the vehicle’s wheels and are an integral part of the suspension system. They bear the weight of the vehicle and help maintain proper wheel alignment and geometry. Axle shafts are designed to withstand the vertical load exerted by the vehicle’s weight and the lateral forces encountered during turns or maneuvering. By providing structural support and connection between the wheels and the drivetrain, axle shafts contribute to the overall stability, handling, and control of the vehicle.

3. Differential Functionality:

Axle shafts are essential for the proper functioning of the differential. The differential allows the wheels to rotate at different speeds while maintaining power distribution. As the vehicle negotiates turns, the inside wheels travel a shorter distance than the outside wheels. The axle shafts, connected to the differential, enable this speed differentiation by allowing the wheels to rotate independently. This differential action helps improve maneuverability, reduce tire wear, and enhance traction by allowing the wheels to maintain proper contact with the road surface.

4. Torque and Load Handling:

Axle shafts are designed to handle the torque and loads generated by the engine and transmitted through the drivetrain. They are engineered to withstand the rotational forces and torsional stress, ensuring efficient power transfer to the wheels. Axle shafts are made from durable materials, such as steel or other high-strength alloys, to withstand these forces and provide reliable performance under various driving conditions.

In summary, the purpose of an axle shaft in a vehicle’s drivetrain is to transmit rotational power from the differential to the wheels. They enable power transfer, provide support for the wheels, contribute to the functionality of the differential, and handle the torque and loads generated by the drivetrain. Axle shafts are essential components that play a vital role in the overall performance, functionality, and stability of a vehicle.

editor by CX 2024-04-24

China Standard Transmission Shaft Drive Shaft Gear Shaft Cardan Shaft Transmission Shaft Rotor Shaft Propeller Shaft Motor Shaft Spline Shaft Steel Shaft Axle Shaft axle barbell

Product Description

Detailed Photos

Product Parameters

|

Brand |

Zhonghe Shengtai |

|

Structure |

FORGING |

|

Material |

Steel, Stainless Steel, Aluminium, Copper, Bronze Or according to customer’s requirement |

|

Processing |

Sawing, Maching, Hobbing, Milling, Shaving, Grinding, Broaching, Heat Treatment, Surface Treatment |

|

Application |

Electrical motors ,Water pump ,gear box spare parts,reducer |

|

Delivery time |

15-30DAYs |

|

Supply capacity |

500 pcs /Month |

|

Certification |

TUV |

Company Profile

CNC Machining Workshop

Our has extensive in-house equipment for both manufacturing and testing. Your parts will be manufactured and inspected with our advanced in-house equipment, Including Precision CNC milling, CNC turning, EDM,We can undertake all kinds of OEM&ODM projects.

Packaging & Shipping

FAQ

Q1:Where can I get product&price information?

A1:Send us e-mail , we will contact you as we receive your mail.

Q2: How soon can I get samples?

A2: Depending on your specific project, it usually takes 10 to 20 days.

Q3:How to enjoy the OEM services?

A3:Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you.

Q4:Can you make machining parts based on our samples?

A4:Yes, we can make measurement based on your samples to make drawings for machining parts making.

Q5: Is it possible to know how are my products going on without visiting your company?

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Full Service |

|---|---|

| Warranty: | Full Service |

| Condition: | New |

| Certification: | TUV |

| Standard: | GB |

| Customized: | Customized |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do axle shafts enhance the overall performance and drivability of vehicles?

Axle shafts play a crucial role in enhancing the overall performance and drivability of vehicles. These components are integral to the drivetrain system and are responsible for transferring power from the differential to the wheels. Here’s a detailed explanation of how axle shafts contribute to improved performance and drivability:

- Power Transmission: Axle shafts are responsible for transmitting power from the differential to the drive wheels. By efficiently transferring torque, axle shafts allow the wheels to rotate and generate forward motion. The proper functioning of axle shafts ensures that power is effectively delivered to the wheels, enabling acceleration, towing capability, and overall propulsion.

- Traction and Stability: Axle shafts, particularly in vehicles equipped with differential systems, play a crucial role in optimizing traction and stability. Differential systems allow for power distribution between the wheels, adjusting torque delivery based on wheel slip conditions. This helps to improve traction on various surfaces, such as slippery roads or uneven terrains. By ensuring better grip and stability, axle shafts contribute to safer and more confident driving experiences.

- Handling and Cornering: Axle shafts influence the handling and cornering characteristics of a vehicle. By transmitting power to the drive wheels, axle shafts enable precise control and responsiveness during steering inputs. Well-designed axle shafts with appropriate strength and flexibility properties contribute to predictable and stable handling, allowing drivers to navigate corners smoothly and maintain control over the vehicle.

- Load-Bearing Capacity: Axle shafts are subjected to significant loads, especially in vehicles that carry heavy loads or tow trailers. Robust axle shafts with adequate load-bearing capacity ensure that the vehicle can handle the weight without experiencing excessive deflection or failure. By providing sufficient strength and durability, axle shafts contribute to the safe and efficient transport of passengers and cargo.

- Efficiency and Fuel Economy: The weight and design of axle shafts can impact the overall efficiency and fuel economy of a vehicle. Lighter axle shafts, such as those made from advanced materials like aluminum or composites, can reduce the unsprung weight of the vehicle. This helps improve suspension response, reduce energy losses, and enhance fuel efficiency. Additionally, optimized designs and reduced friction in axle shafts contribute to more efficient power transmission, maximizing the energy utilization of the drivetrain system.

- Durability and Reliability: Axle shafts are subjected to various stresses and operating conditions, including high torque, vibrations, and impacts. High-quality axle shafts constructed from durable materials, engineered with appropriate geometries, and manufactured using advanced techniques offer enhanced durability and reliability. Reliable axle shafts minimize the risk of failures or breakdowns, contributing to the overall dependability of the vehicle.

In summary, axle shafts enhance the overall performance and drivability of vehicles through efficient power transmission, improved traction and stability, enhanced handling and cornering, adequate load-bearing capacity, increased efficiency and fuel economy, and enhanced durability and reliability. These components play a critical role in ensuring optimal power delivery, control, and safety, ultimately enhancing the driving experience and satisfaction of vehicle owners.

How do axle shafts contribute to a vehicle’s stability and handling?

Axle shafts play a crucial role in contributing to a vehicle’s stability and handling characteristics. They are integral components of the suspension and drivetrain systems, affecting how the vehicle distributes power, maintains traction, and responds to steering inputs. Here’s a detailed explanation of how axle shafts contribute to a vehicle’s stability and handling:

- Power Distribution: Axle shafts transmit power from the drivetrain to the wheels, allowing the vehicle to move forward or backward. The distribution of power between the wheels is essential for maintaining stability and preventing wheel slippage. By transferring torque evenly to the wheels, axle shafts help optimize traction and prevent excessive power loss, ensuring that the vehicle stays stable and controlled during acceleration or deceleration.

- Traction Control: Axle shafts, particularly those equipped with differential mechanisms, help maintain traction by allowing the wheels to rotate at different speeds when necessary. This feature is especially important during turns or when driving on uneven surfaces. The differential compensates for differences in wheel rotation, enabling the vehicle to maintain stability and grip by preventing wheel spin or loss of control.

- Suspension Geometry: Axle shafts are integrated into the suspension system, connecting the wheels to the differential or transaxle. The positioning and design of axle shafts influence the suspension geometry, including factors like camber, caster, and toe. Proper suspension geometry is crucial for stability, predictable handling, and optimal tire contact with the road surface. Well-engineered axle shafts ensure that the suspension components work harmoniously to maintain stability and enhance handling characteristics.

- Steering Response: In vehicles with front-wheel drive or all-wheel drive configurations, axle shafts are responsible for transmitting power to the front wheels while also allowing for steering inputs. This design affects the vehicle’s steering response and handling. High-quality axle shafts with minimal play or backlash contribute to precise steering control, allowing the driver to make accurate and predictable maneuvers. Axle shafts that provide a direct and responsive connection between the drivetrain and front wheels enhance the overall handling and stability of the vehicle.

- Weight Distribution: The weight distribution of a vehicle affects its stability and handling characteristics. Axle shafts, particularly those in rear-wheel drive vehicles, support the weight of the vehicle’s rear end. By properly distributing the weight across the axles, axle shafts help maintain a balanced and stable platform. This balanced weight distribution enhances the vehicle’s overall stability and allows for better handling during cornering, reducing the risk of oversteer or understeer.

- Impact on Suspension Tuning: Axle shafts can have an impact on the tuning and performance of the suspension system. Upgrading to high-performance axle shafts, such as those made from stronger materials or featuring improved designs, can enhance the overall rigidity and responsiveness of the suspension. This, in turn, improves the vehicle’s stability and handling, allowing for more precise control during aggressive driving or challenging road conditions.

It’s important to note that while axle shafts contribute significantly to a vehicle’s stability and handling, they work in conjunction with other components such as suspension, tires, steering system, and chassis design. The overall performance and characteristics of a vehicle’s stability and handling are the result of a complex interaction between these components.

In summary, axle shafts contribute to a vehicle’s stability and handling by ensuring proper power distribution, maintaining traction control, influencing suspension geometry, providing responsive steering, contributing to balanced weight distribution, and impacting suspension tuning. High-quality axle shafts that are properly engineered and integrated into the vehicle’s systems enhance stability, improve handling characteristics, and allow for a more controlled and enjoyable driving experience.

How does axle shaft length and material affect a vehicle’s performance?

The length and material of an axle shaft can have an impact on a vehicle’s performance in several ways. Both factors play a role in determining the vehicle’s handling, power delivery, efficiency, and overall drivability. Here’s a detailed explanation of how axle shaft length and material affect a vehicle’s performance:

Axle Shaft Length:

The length of the axle shaft refers to the distance between the differential or transaxle and the wheel hub. The axle shaft length can influence the following aspects of a vehicle’s performance:

- Traction and Stability: A longer axle shaft can provide increased stability and traction, especially in situations where weight transfer occurs during acceleration or cornering. The longer length helps distribute the vehicle’s weight more evenly between the wheels, enhancing grip and stability.

- Turning Radius: The length of the axle shaft affects a vehicle’s turning radius. Generally, a shorter axle shaft allows for a tighter turning radius, making it easier to maneuver in tight spaces or negotiate sharp turns. On the other hand, a longer axle shaft may result in a larger turning radius, requiring more space for turning maneuvers.

- Ground Clearance: The length of the axle shaft can impact a vehicle’s ground clearance. A shorter axle shaft may provide higher ground clearance, which can be advantageous for off-road vehicles or those designed for rugged terrain. Conversely, a longer axle shaft may reduce ground clearance, potentially limiting the vehicle’s ability to navigate obstacles.

Axle Shaft Material:

The material used in the construction of an axle shaft can significantly influence a vehicle’s performance characteristics. Here are some ways in which axle shaft material can impact performance:

- Strength and Durability: The material of the axle shaft determines its strength and durability. High-strength materials, such as alloy steel or specialized composites, can withstand higher torque loads and provide enhanced durability, making them suitable for high-performance or heavy-duty applications. Stronger materials also contribute to improved reliability and reduced risk of axle shaft failure.

- Weight Reduction: The choice of lightweight materials, such as aluminum or carbon fiber, for the axle shaft can help reduce overall vehicle weight. A lighter axle shaft contributes to improved fuel efficiency, handling, and acceleration. It also reduces unsprung weight, which positively affects the vehicle’s suspension dynamics and responsiveness.

- Flexibility and Damping: Some axle shaft materials possess inherent flexibility or damping properties that can influence the vehicle’s ride quality and handling characteristics. Certain composite materials or designs can help absorb vibrations and shocks from the road surface, contributing to a smoother and more comfortable ride.

- Cost and Manufacturing: The choice of axle shaft material can impact manufacturing costs and feasibility. Some materials may be more expensive or require specialized manufacturing processes, affecting the overall cost of the vehicle. Additionally, material availability and ease of fabrication can influence the practicality of using certain materials for axle shaft construction.

It’s important to note that axle shaft length and material selection are typically determined by the vehicle manufacturer based on various considerations, including the intended purpose of the vehicle, performance targets, cost factors, and engineering requirements. Optimizing axle shaft length and material can contribute to achieving the desired balance of performance, handling, durability, and efficiency for a specific vehicle application.

editor by CX 2024-04-10

China Good quality Precision Transmission /Drive/Axle/Auto/Spline/Machinery Parts/ Rotor Gear Customized Machining Knurling Shaft bad axle symptoms

Product Description

Detailed Photos

Product Parameters

|

Pressure Angle |

Customized |

|

Place of Origin |

Qing Dao, China |

|

Outer Diameter |

Customized |

|

Surface Treatment |

Grinding |

|

Material |

Carbon Steel |

|

Size |

Customized Size |

|

Type |

OEM Parts |

|

Certificate |

ISO 9001 |

|

Feature |

M1~40 |

Company Profile

We do not pursue low labor costs, but insist on providing the best quality products and the best services to customers in order to maintain technical autonomy and quality assurance. We are good at small batch, multi-variety gear production and customized orders.

Packaging & Shipping

FAQ

Q1: Can I get some samples?

A: Yes, sample order is available for quality check and market test. But you have to pay the sample cost and express cost.

Q2: Do you receive customized order?

A: Yes, ODM & OEM are welcomed.

Q3: What’s the lead time?

A: According to the order quantity, small order usually need7~10 days, big order need negotiation.

Q4: What’s your warranty terms?

A: We supply 12 months warranty time.

Q5: What’s your payment terms?

A: We receive Escrow, T/T,

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery |

|---|---|

| Hardness: | Soft Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Spur Gear |

| Type: | Circular Gear |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there potential challenges or limitations to using specific axle shafts?

Using specific axle shafts in vehicles can come with challenges or limitations depending on various factors such as the design of the vehicle, the intended use, and the specific characteristics of the axle shafts. Here’s a detailed explanation of potential challenges or limitations associated with specific axle shafts:

- Compatibility: One challenge is ensuring compatibility between the axle shafts and the vehicle’s drivetrain configuration, suspension system, and overall design. Axle shafts must be designed to fit the specific vehicle model and its corresponding drivetrain layout. Using incompatible axle shafts can lead to improper fitment, compromised performance, or even mechanical failures.

- Strength and Durability: Depending on the vehicle’s weight, power output, and intended use, specific axle shafts may have limitations in terms of strength and durability. Axle shafts subjected to heavy loads, aggressive driving, or off-road conditions may require higher-strength materials or specialized designs to withstand the forces and torque applied to them. Using axle shafts that are not adequately designed for the vehicle’s demands can result in premature wear, bending, or breakage.

- Performance Trade-offs: Different types of axle shafts offer different performance trade-offs. For example, solid axle shafts may provide durability and simplicity but can result in a harsher ride quality and limited independent wheel movement. On the other hand, CV (constant velocity) axle shafts offer smoother power delivery and greater wheel articulation but may have limitations in terms of torque capacity and durability under extreme conditions. It’s important to consider the specific requirements and priorities of the vehicle’s performance and select axle shafts accordingly.

- Cost and Availability: Certain axle shafts, especially those designed for specialized applications or high-performance vehicles, may be more expensive or harder to source compared to standard axle shafts. Limited availability can pose challenges when it comes to replacement or upgrade options. Additionally, aftermarket axle shafts might not always meet the same quality standards as original equipment manufacturer (OEM) parts, which could impact their performance and reliability.

- Modifications and Customization: Modifying or customizing axle shafts can introduce additional challenges. Altering axle shafts to accommodate different drivetrain configurations, wheel sizes, or suspension setups may require specialized knowledge, engineering expertise, and fabrication skills. Improper modifications can negatively affect the vehicle’s stability, handling, and safety.

- Serviceability: Some specific axle shafts might have limited serviceability or require specialized tools or expertise for maintenance, repair, or replacement. This can impact the availability and cost of servicing the vehicle. It’s important to consider the long-term serviceability and support for specific axle shafts when selecting them for a vehicle.

It’s crucial to consult with knowledgeable professionals, such as automotive engineers or experienced mechanics, to ensure the appropriate selection and installation of axle shafts for a specific vehicle. They can provide valuable insights and guidance based on the vehicle’s requirements, intended use, and potential limitations associated with specific axle shafts.

In summary, potential challenges or limitations of using specific axle shafts include compatibility issues, limitations in strength and durability, performance trade-offs, cost and availability considerations, challenges related to modifications or customization, and serviceability concerns. A careful assessment of these factors is essential to ensure the optimal performance, safety, and reliability of the vehicle.

How does axle shaft quality impact the overall durability of a vehicle?

The quality of axle shafts has a significant impact on the overall durability of a vehicle. Axle shafts play a crucial role in transmitting power from the drivetrain to the wheels and supporting the weight of the vehicle. Here’s a detailed explanation of how axle shaft quality affects the durability of a vehicle:

- Strength and Load Capacity: High-quality axle shafts are typically constructed from strong and durable materials, such as forged steel or alloy steel. These materials offer increased tensile and yield strength, allowing the axle shafts to handle higher torque loads and support the weight of the vehicle more effectively. Axle shafts with higher load capacities and structural integrity are less prone to bending, breaking, or premature failure, ensuring long-term durability.

- Resistance to Fatigue: Axle shafts are subjected to repeated and varying loads during vehicle operation, which can lead to metal fatigue over time. High-quality axle shafts are designed and manufactured to withstand these cyclic loads without developing cracks or fractures. They undergo rigorous testing and quality control processes to ensure resistance to fatigue, enhancing the overall durability of the vehicle.

- Corrosion Resistance: Axle shafts are exposed to various environmental factors, including moisture, road salt, and debris. High-quality axle shafts often feature protective coatings or treatments, such as galvanization or specialized finishes, to enhance corrosion resistance. These coatings prevent rust and corrosion from compromising the structural integrity of the axle shafts, contributing to their long-term durability.

- Precision Engineering: Axle shafts with superior quality are precisely engineered to meet strict tolerances and specifications. They are manufactured using advanced techniques, such as forging or CNC machining, to ensure dimensional accuracy and proper fitment with other drivetrain components. Precise engineering eliminates excessive play or misalignment, reducing stress on the axle shafts and enhancing the overall durability of the vehicle.

- Heat Treatment: High-quality axle shafts often undergo specialized heat treatment processes, such as induction hardening or tempering. These heat treatment techniques improve the hardness and strength of the axle shafts, making them more resistant to wear, deformation, and surface damage. Heat-treated axle shafts exhibit enhanced durability and longevity, even under demanding driving conditions.

- Manufacturer Reputation: The reputation of the axle shaft manufacturer is also a crucial factor in determining the quality and durability of the product. Reputable manufacturers with a history of producing reliable and high-quality axle shafts are more likely to deliver durable and long-lasting components. Choosing axle shafts from trusted manufacturers reduces the risk of premature failure and ensures higher overall vehicle durability.

It’s important to note that the durability of a vehicle is influenced by various other factors, including proper maintenance, driving conditions, and overall vehicle design. However, the quality of axle shafts significantly contributes to the vehicle’s ability to withstand demanding loads, harsh environments, and extended service life.

When replacing or upgrading axle shafts, it is crucial to select high-quality components that match the vehicle’s specifications and intended use. Professional installation by experienced technicians is recommended to ensure proper fitment and compatibility, further enhancing the durability and performance of the vehicle.

In summary, axle shaft quality directly impacts the overall durability of a vehicle by providing increased strength, resistance to fatigue and corrosion, precision engineering, heat treatment, and the reliability associated with reputable manufacturers. Investing in high-quality axle shafts contributes to a more durable and reliable vehicle that can withstand the demands of various driving conditions and extended use.

How does axle shaft length and material affect a vehicle’s performance?

The length and material of an axle shaft can have an impact on a vehicle’s performance in several ways. Both factors play a role in determining the vehicle’s handling, power delivery, efficiency, and overall drivability. Here’s a detailed explanation of how axle shaft length and material affect a vehicle’s performance:

Axle Shaft Length:

The length of the axle shaft refers to the distance between the differential or transaxle and the wheel hub. The axle shaft length can influence the following aspects of a vehicle’s performance:

- Traction and Stability: A longer axle shaft can provide increased stability and traction, especially in situations where weight transfer occurs during acceleration or cornering. The longer length helps distribute the vehicle’s weight more evenly between the wheels, enhancing grip and stability.

- Turning Radius: The length of the axle shaft affects a vehicle’s turning radius. Generally, a shorter axle shaft allows for a tighter turning radius, making it easier to maneuver in tight spaces or negotiate sharp turns. On the other hand, a longer axle shaft may result in a larger turning radius, requiring more space for turning maneuvers.

- Ground Clearance: The length of the axle shaft can impact a vehicle’s ground clearance. A shorter axle shaft may provide higher ground clearance, which can be advantageous for off-road vehicles or those designed for rugged terrain. Conversely, a longer axle shaft may reduce ground clearance, potentially limiting the vehicle’s ability to navigate obstacles.

Axle Shaft Material:

The material used in the construction of an axle shaft can significantly influence a vehicle’s performance characteristics. Here are some ways in which axle shaft material can impact performance:

- Strength and Durability: The material of the axle shaft determines its strength and durability. High-strength materials, such as alloy steel or specialized composites, can withstand higher torque loads and provide enhanced durability, making them suitable for high-performance or heavy-duty applications. Stronger materials also contribute to improved reliability and reduced risk of axle shaft failure.

- Weight Reduction: The choice of lightweight materials, such as aluminum or carbon fiber, for the axle shaft can help reduce overall vehicle weight. A lighter axle shaft contributes to improved fuel efficiency, handling, and acceleration. It also reduces unsprung weight, which positively affects the vehicle’s suspension dynamics and responsiveness.

- Flexibility and Damping: Some axle shaft materials possess inherent flexibility or damping properties that can influence the vehicle’s ride quality and handling characteristics. Certain composite materials or designs can help absorb vibrations and shocks from the road surface, contributing to a smoother and more comfortable ride.

- Cost and Manufacturing: The choice of axle shaft material can impact manufacturing costs and feasibility. Some materials may be more expensive or require specialized manufacturing processes, affecting the overall cost of the vehicle. Additionally, material availability and ease of fabrication can influence the practicality of using certain materials for axle shaft construction.

It’s important to note that axle shaft length and material selection are typically determined by the vehicle manufacturer based on various considerations, including the intended purpose of the vehicle, performance targets, cost factors, and engineering requirements. Optimizing axle shaft length and material can contribute to achieving the desired balance of performance, handling, durability, and efficiency for a specific vehicle application.

editor by CX 2024-04-08

China Standard Gear Center Axle Excavator Parts Inner Hex Customized Fasteners Replacement Motor Shaft cv axle replacement

Product Description

Product Description

| Name | Gear Center Axle Excavator Parts Inner Hex Customized Fasteners Replacement Motor Shaft | ||

| Cold Heading | Transport Package | Plastic Bag, Carton Package, Pallet Package | |

| Specialty | OEM, ODM | Production Capacity | 10 Million Per Month |

| Sample | Free Sample If in Store | QC Control | Inspect 30mins in Production and Before Delivery |

| Heat Treatment | Hot-Working | QC Equipment | Salt Spray Machine, Hardness Testor, Caliper |

| Delivery time | 15-30 Days | Service | Quickly response |

| Application | Machinery, Chemical Industry, Environmental, Building | Brand | Linork |

| Applied Area | Building, Machinery, Auto, Car Wheel | Origin | HangZhou |

Detailed Photos

Company Profile

Packaging & Shipping

•If the quantity of order is not very big,we could send them to you by express delivery,such as TNT,DHL,UPS OR EMS etc.

•If order is big ,we will advise you use Air Shipping or Sea Shipping through your nominated forwarder agent.Our long-term cooperated agent also available.

FAQ

Q1: What are your main products?

A: At present, the company produces more than 1000 kinds of different fasteners, such as automobile standard parts, automobile non-standard parts, automobile lamps and fittings, automobile non-standard nuts (grade 8, 10, 12), automobile interior parts, low-voltage electrical components, stamping parts, high-strength screws (grade 8.8, 9.8, 10.9, 12.9), etc. And plastic parts, rubber rings, die casting more than 100 different products.

Q2: When will I know the price?

A: We usually offer within 12 hours, not more than 24 hours. In case of emergency, please contact us directly by phone or email.

Q3: Do you have enough capacity?

A: The current production capacity of the company is about 45,000 tons of steel, including 30,000 tons of wire and 15,000 tons of plate.

Q4: I’m not sure what screws to use, I need a little engineering help. Do you offer any help?

A: We have A complete engineering department that can provide you with the most suitable screws according to your product.

Q5: I need custom screws, but there are no screws listed on your website. What should I do?

A: Our professional engineers can design professional drawings according to your requirements, and can also produce according to the drawings you provide

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Are there potential challenges or limitations to using specific axle shafts?

Using specific axle shafts in vehicles can come with challenges or limitations depending on various factors such as the design of the vehicle, the intended use, and the specific characteristics of the axle shafts. Here’s a detailed explanation of potential challenges or limitations associated with specific axle shafts:

- Compatibility: One challenge is ensuring compatibility between the axle shafts and the vehicle’s drivetrain configuration, suspension system, and overall design. Axle shafts must be designed to fit the specific vehicle model and its corresponding drivetrain layout. Using incompatible axle shafts can lead to improper fitment, compromised performance, or even mechanical failures.

- Strength and Durability: Depending on the vehicle’s weight, power output, and intended use, specific axle shafts may have limitations in terms of strength and durability. Axle shafts subjected to heavy loads, aggressive driving, or off-road conditions may require higher-strength materials or specialized designs to withstand the forces and torque applied to them. Using axle shafts that are not adequately designed for the vehicle’s demands can result in premature wear, bending, or breakage.

- Performance Trade-offs: Different types of axle shafts offer different performance trade-offs. For example, solid axle shafts may provide durability and simplicity but can result in a harsher ride quality and limited independent wheel movement. On the other hand, CV (constant velocity) axle shafts offer smoother power delivery and greater wheel articulation but may have limitations in terms of torque capacity and durability under extreme conditions. It’s important to consider the specific requirements and priorities of the vehicle’s performance and select axle shafts accordingly.

- Cost and Availability: Certain axle shafts, especially those designed for specialized applications or high-performance vehicles, may be more expensive or harder to source compared to standard axle shafts. Limited availability can pose challenges when it comes to replacement or upgrade options. Additionally, aftermarket axle shafts might not always meet the same quality standards as original equipment manufacturer (OEM) parts, which could impact their performance and reliability.

- Modifications and Customization: Modifying or customizing axle shafts can introduce additional challenges. Altering axle shafts to accommodate different drivetrain configurations, wheel sizes, or suspension setups may require specialized knowledge, engineering expertise, and fabrication skills. Improper modifications can negatively affect the vehicle’s stability, handling, and safety.

- Serviceability: Some specific axle shafts might have limited serviceability or require specialized tools or expertise for maintenance, repair, or replacement. This can impact the availability and cost of servicing the vehicle. It’s important to consider the long-term serviceability and support for specific axle shafts when selecting them for a vehicle.

It’s crucial to consult with knowledgeable professionals, such as automotive engineers or experienced mechanics, to ensure the appropriate selection and installation of axle shafts for a specific vehicle. They can provide valuable insights and guidance based on the vehicle’s requirements, intended use, and potential limitations associated with specific axle shafts.

In summary, potential challenges or limitations of using specific axle shafts include compatibility issues, limitations in strength and durability, performance trade-offs, cost and availability considerations, challenges related to modifications or customization, and serviceability concerns. A careful assessment of these factors is essential to ensure the optimal performance, safety, and reliability of the vehicle.

What are the advantages of using high-performance or heavy-duty axle shafts?

Using high-performance or heavy-duty axle shafts can offer several advantages in terms of strength, durability, and performance. These specialized axle shafts are designed to handle increased torque loads, provide improved power delivery, and withstand the demands of challenging applications. Here’s a detailed explanation of the advantages of using high-performance or heavy-duty axle shafts: